By James W. Jordan, P.E., S.E.

From the February 2022 Issue

In May 2015, Rimkus became the first company to receive approval from the Federal Aviation Administration (FAA) to utilize quadcopter drones (also referred to as unmanned aircraft systems, or UAS) for aerial inspections and surveys of structures and facilities to conduct forensic inspections. Since that time, we have seen a tremendous surge of drone use for building inspections including the evaluation of roofs and exterior façades. The purpose of this article is to provide some insight on the use of drones for roof and facade inspections, and to point out key advantages and shortcomings.

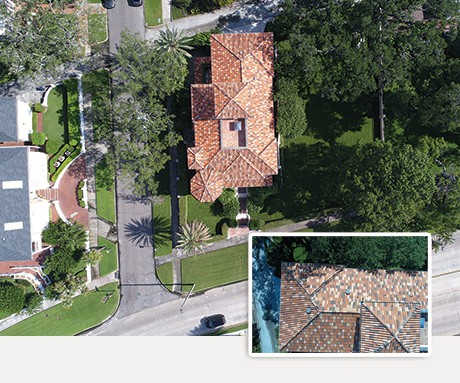

In our experience, drone use for storm damage evaluation is particularly valuable for brittle and malleable roofing materials such as slate, concrete/clay tile, and metal. The effects of damaging hail or other impacts on such materials typically exhibit visible fractures (brittle materials) or significant dents (metal materials). Wind damage to such materials typically exhibits missing/displaced areas or visibly broken/punctured or dented conditions. Furthermore, the inspection of roofing or façade materials for some structures may only be accomplished by crane/manlift or drone. In some instances, these materials may be unsafe to step upon (or touch). (See Figures 1, 2 and 3 for examples.)

In our experience, the use of drone imagery to evaluate certain types of roof coverings may result in misleading or inaccurate findings. We have reviewed reports from some drone inspection companies that claim to use “artificial intelligence” (AI) to identify storm damage, but they failed to recognize non-storm-related conditions—thus questioning the validity of the AI system. Some of these firms appear to simply mark every localized anomaly in their drone images as storm damage. The summary that follows describes the limitations of drone use for the inspection of certain types of roofing materials.

Asphalt Shingles

Visible anomalies sometimes mistaken as hail damage include spot algae stains, asphalt drippings (manufacturing/installation issue), bird droppings, marring/scuffs from foot traffic, golf ball strikes, lichen growth, blistering, and flaking. Can the drone inspector and/or AI system discern these from hail damage? They may recognize some of these anomalies, but not likely all of them.

Bruising of shingles from hailstone strikes results in the fracturing of the base mat, which requires tactile examination to confirm. Inspection with only binoculars or drone cameras will not accomplish this.

Granule loss assessment is a significant part of hail damage determination. One must determine if hail impacts caused localized granule loss that exposed the asphalt base mat to such an extent that the remaining service life of the affected shingle is reduced. This requires an assessment of the overall condition of the affected shingle. If the shingle was already substantially deteriorated with widespread granule loss, the additional granule loss from hail impact may have no effect on the shingle’s remaining service life. Can drone imagery with an AI analysis system perform this type of assessment? Not presently, to our knowledge.

Wind damage evaluation typically involves a tactile examination of the roof shingles. Hidden wind damage is found by checking for loose shingles, then gently lifting to search for tears hidden beneath the overlying shingles and to check for fasteners that pulled through. In some cases, we find multiple rows of shingles that wind lifted and tore, but they laid back into place hiding the physical damage. An inspection via binoculars or with drone imagery will miss these conditions.

Wind damage evaluation also requires tactile examination to determine if installation or material defects are a factor. For example, over-driven fasteners are sometimes mistaken as wind damage. An insufficient number of fasteners per shingle, fasteners installed too short, high-nailing, failure of sealant strips to activate, and premature corrosion of fasteners are examples of hidden conditions that make shingles prone to damage from moderate wind events—yet none of these conditions would be visible in drone imagery.

A determination of repairability is often a part of a roof inspection for storm damage. A tactile examination is typically needed to determine if shingles have sufficient pliability and strength to survive the manipulation required to replace isolated or groups of shingles.

Wood Shakes/Shingles

Hail damage assessment typically involves finding a hail impact mark associated with a fresh split in the affected shake/shingle. In our experience, gently pressing on the two bottom corners of a shake/shingle with an impact mark is the best way to determine if there is a fresh split. They otherwise will typically stay hidden. One must first find the hail impact marks, then conduct the tactile examination to see if there are fresh splits. If there are no fresh splits or fractures, and the hail mark is essentially a temporary cosmetic condition (i.e., marks that fade with time), then there is no damage. An inspection via binoculars or with drone imagery may only find the most obvious splits and fractures but will likely miss those that are found by tactile examination.

Wind damage to wood shakes/shingles is typically obvious (in the form of missing or broken shakes/shingles). On some occasions, “lifted” shakes/shingles may be present—and one may need to determine if it was caused by wind or some other means. This typically requires tactile examination to determine how the affected shakes/shingles were installed. If installed on spaced board sheathing, some of the fasteners may have missed the roof deck, or the nails may have been too short. Binocular/drone inspection methods will miss this, particularly if one must go into the attic to check the deck conditions and if the fasteners extended through it (which may be required depending on the deck thickness).

Slate

In our experience, hail impact damage to slate is typically visible and does not require tactile examination. Inspection via binoculars, camera equipment with a good zoom lens, or drone imagery is fairly common for this assessment.

Wind damage to slate is often obvious and visible; however, tactile examination is often required to evaluate the hidden installation features of the affected slate. Fasteners that miss spaced sheathing boards, short fasteners, severely deteriorated fasteners, and severely deteriorated sheathing are examples of hidden conditions that will make the slate prone to damage from moderate wind events. Binocular/drone inspection methods will miss these conditions.

The Full Picture

In summary, an experienced roof inspector who accesses a roof to conduct a visual and tactile examination would be in a position to make the most accurate assessment. Opinions developed solely on drone imagery may be easily challenged for certain roofing materials and will not likely withstand scrutiny when considering conditions that require tactile examination for evaluation. In our experience, consideration of hidden conditions is often necessary to fully understand the presence, cause, and extent of damage, and to determine if the roof covering is repairable.

Jordan is Vice President, Property Practice for Rimkus Consulting Group, Inc., a firm headquartered in Houston, TX. He is a licensed professional engineer in 12 states and a licensed structural engineer in Illinois. His more than 35 years of experience with structural design and forensic engineering include work in the commercial, residential, industrial, power/energy, municipal, agricultural, and manufacturing sectors. He has performed hundreds of evaluations of structures affected by construction defects, moisture intrusion, foundation movement, explosions, vibrations, catastrophic storms, earthquakes, vehicle impacts, and fires. In his current position, Jordan is responsible for overseeing the technical operations of the largest practice group at Rimkus.

Do you have a comment? Share your thoughts in the Comments section below, or send an e-mail to the Editor at acosgrove@groupc.com.

![[VIDEO] Collect Asset Data at the Speed of Walking a Building](https://facilityexecutive.com/wp-content/uploads/2024/02/maxresdefault-324x160.jpg)