By Jason Carter

From the April 2021 Issue

As HVAC systems age, there are predictable challenges facility managers and building owners can expect. Depending on their condition, older systems may not perform as they once did, resulting in lower efficiency, poor indoor air quality (IAQ), or occupant discomfort. Even if they don’t feel it directly, facility managers and building owners likely see the evidence in high utility bills as well as maintenance and repair costs. So how can facility managers overcome these challenges while managing costs? Quick fixes may provide a short-term solution, but best practices call for a deeper, more holistic evaluation of systems.

The first step to finding this solution is a full building analysis. Conducting an analysis on a commercial rooftop unit first determines whether a retrofit makes more sense than replacing the entire unit. If a retrofit is possible, there are two approaches to consider: a standard or a deep retrofit.

In a standard retrofit, economizers or controls are added to a unit in order to reduce energy as well as maintenance costs. Two examples include replacing the inlet guide vanes with a variable frequency drive (VFD) on the supply fan to vary airflow between spaces, or replacing a multizone rooftop, which constantly runs heating and cooling with control from dampers, with a variable air volume (VAV) system.

Also known as continuous commissioning or retro-commissioning, a deep energy retrofit (DER) is completed with a thorough analysis of building systems in order to maximize energy savings. Utility savings then effectively pay for the equipment, much like a performance contract. Integrating BACNet or another building automation system in order to monitor and optimize energy use is an example of a DER. Whether standard, DER, or a combination of the two, it’s important that HVAC retrofits incorporate compliant solutions specific to a building’s challenges to help facility executives accomplish specific cost savings and air quality goals.

Reducing Repairs And Maintenance

HVAC maintenance, repair, and overhaul (MRO) are a significant outlay for facility managers. A DER solution such as smart controls provide continuous monitoring and reliable diagnostic feedback that helps prevent issues before they arise, lowering maintenance and repair costs.

Plug-and-play smart controls are thermostat-ready and can integrate with BACNet control systems. With no configuration and no field programming required, smart equipment controls provide a self-test diagnostic startup report and have single-zone VAV and functionality.

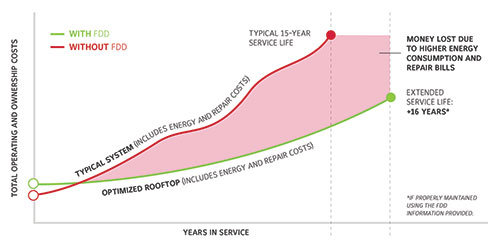

Some smart controls include fault detection and diagnostics (FDD) that help facilities teams get the most out of their rooftop units. FDD technology uses multiple sensors to continuously monitor refrigeration circuit temperatures and pressures, economizer operation, and outdoor humidity and temperatures. FDD algorithms then process the collected data and deliver detailed alerts if issues arise, helping facility management ensure equipment is always performing as specified (see Figure 1).

By monitoring critical variables, facility executives can respond to issues before they first arise, taking a proactive rather than reactive approach to HVAC management.

Increasing Energy Savings

When completing a retrofit, it’s vital to ensure that specified equipment meets existing energy standards. Future standards, like the new Department of Energy minimum efficiency standards that take effect in 2023 and updated ASHRAE 90.1 standards, should be considered, too. In addition to efficiency standards, rebates and LEED requirements can also drive equipment specification. To help buildings meet these standards and earn incentives, RTU manufacturers have made a number of efficiency-enhancing innovations, including airflow control.

If it’s within budget and possible to work into the existing space, VAV is usually the top airflow control choice because it saves fan power costs and also provides better occupant comfort. VAV controls offer significant energy savings by using a variable frequency drive and pressure transducer to maintain static pressure in the supply duct.

But budget and design don’t always allow for a VAV system, and its capabilities aren’t necessary for all applications. Discrete fan control is an option for constant air volume (CAV) systems that stages fan compressors to improve energy efficiency as well as comfort and performance. This type of single-zone airflow control is ideal for spaces like warehouses. Unlike the typical single-zone system operation, continuous reset single-zone (CRSZ) control is an option that operates with the minimum fan speed needed to maximize energy savings and comfort. This can also support passive dehumidification.

Depending on the geolocation, free cooling and other economizer controls can provide efficient cooling. In locations that fall below a certain temperature at night (typically 55°F), an economizer brings in outdoor air to cool a space without the use of compressors or the unit’s full cooling capacity. Different types of controls, including dry bulb, enthalpy, and dual enthalpy, bring in this free cooling.

ASHRAE 90.1 indicates which economizers and controls must be used in which climate zones. Ideal for locations where humidity isn’t a concern, dry bulb controls will bring in air without engaging the compressor when ambient outdoor temperature is at or below the set temperature. Enthalpy does the same but can operate in a wider temperature range by also looking at humidity. Both options can run the compressor just enough to cool outside air to the set temperature when needed. When outdoor temperatures and humidity allow it, both can be more energy efficient than cycling returned air. With an outdoor and return enthalpy sensor, dual enthalpy compares the return conditions to outdoor conditions to decide which option will use less energy to cool the space.

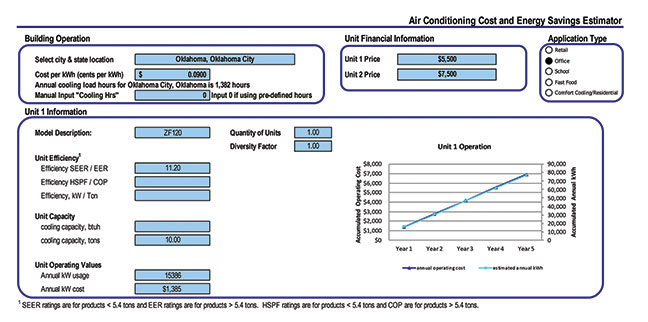

Some manufacturers offer free energy saving calculators and other tools to help engineers and facility managers determine ROI and energy savings of these systems based on their location. By entering specific application parameters, users can see projected scenarios to help them make informed decisions (see Figure 2).

Improving Occupant Health And Comfort

To ensure occupant health and comfort in retrofits, equipment must comply with ASHRAE 62.1. This standard specifies minimum ventilation rates for acceptable indoor air quality. But there are also other considerations when improving a building’s IAQ.

Filtration is vital to cultivating healthy buildings. Some light commercial units are designed to change from 2- to 4-inch filters, which provide more precise filtering. And, in addition to efficiency, demand control ventilation can help bring fresh air into buildings by increasing the level of outdoor air intake.

Ultraviolet lights are also very popular for retrofits. These systems can kill or inactivate mold, mildew, dander, bacteria, and viruses by using UV-C light to damage the nucleic acids and proteins of pathogens. These devices can be mounted in ductwork or packaged units, helping them stay clean and run more efficiently. They can also help combat the mold and bacteria often found in high-condensation areas of system components like the indoor coil.

Completing A Successful Retrofit

When evaluating for a retrofit, facility executives will benefit from drawing upon proven experience and expertise. It’s advantageous to partner with an expert who has service, controls, and equipment knowledge and a manufacturer that offers the equipment to meet a variety of needs. A rep with a local service department will be able to handle any support needs, too. Equipment that minimizes repairs, saves energy, and improves health, backed by this level of expertise, will help ensure retrofits provide efficient performance and comfort for years to come.

Carter is a light commercial application engineering manager at Johnson Controls based in Norman, OK. He graduated from the Georgia Institute of Technology with a Bachelor of Science in Industrial Engineering in 2002. After completing his degree, he worked as a Commercial Sales Engineer for seven years at Trane before joining Johnson Controls in 2008. He’s an LEED Accredited Professional and has been involved in ASHRAE, CEE, and LEED committees.

Carter is a light commercial application engineering manager at Johnson Controls based in Norman, OK. He graduated from the Georgia Institute of Technology with a Bachelor of Science in Industrial Engineering in 2002. After completing his degree, he worked as a Commercial Sales Engineer for seven years at Trane before joining Johnson Controls in 2008. He’s an LEED Accredited Professional and has been involved in ASHRAE, CEE, and LEED committees.

Do you have a comment? Share your thoughts in the Comments section below, or send an e-mail to the Editor at acosgrove@groupc.com.

Want to read more about facility management and HVAC?

Check out all the recent HVAC Factor columns from Facility Executive magazine.

![[VIDEO] Collect Asset Data at the Speed of Walking a Building](https://facilityexecutive.com/wp-content/uploads/2024/02/maxresdefault-324x160.jpg)

An HVAC wet switch/float switch, also known as a condensate overflow switch, serves to prevent this pan from overflowing if the AC drain stops working properly. The switch is activated when the level of the water in the pan comes above a certain point, causing the switch mechanism to trip/float to rise. No matter where your HVAC unit is located, it’s important to install a float switch or, if appropriate for your unit, a condensate pump. An overflow on the top level of your home could cause significant damage to the floors below and result in microbial growth, mold and hazardous living conditions.

Looking at Figure 1, it is clear that smart control is important for hvac fault detection and diagnostics. An hvac user can easily manage and maintain his device smartly. It is remarkable that FDD technology uses multiple sensors to continuously monitor the refrigeration circuit temperature and pressure, economist operation and external humidity and temperature. The FDD algorithm then processes the collected data and provides detailed alerts in case of problems, helping to ensure facility management that the tools are always working as specified.