By Aimee Sanford

From the May 2014 issue of Today’s Facility Manager

Sheetrock, plaster, t-grid, acoustic, resilient, coffered, beams… when a ceiling needs renovating or adjustment, the possibilities are endless and lead to questions of design and functionality—but what is best?

Different ceiling styles and materials all present different benefits and drawbacks. Here are a few of the most common ceiling issues that facility managers (fms) may encounter in existing facilities, along with solutions to address the problems.

We are doing a ground up renovation. What are the options? One of the most common ceiling substrates is sheetrock or drywall. This ceiling type in its simplest form is an 8′ or higher flat surface that is uncluttered and doesn’t call attention to itself. It is also easily accessible with a stepladder.

Sheetrock ceilings can also be constructed in a variety of raised shapes like vaulted, cathedral, coffered, dome, or cove. These shapes create the illusion of a larger space and are very attractive, but the more intricate the design, the more costly it is to create. Also, intricate designs such as cathedral are not always the most practical when it comes to energy efficiency.

When working with a sheetrock ceiling, fms may want to increase visual appeal by adding beams, wood paneling, or tin elements—all three of which are popular in interior design right now.

In commercial applications, the most common ceiling type is a suspended drop tile grid system. These assemblies are used in many office environments and basements because they hide, and provide easy access to, mechanical “clutter” such as wires, pipes, and HVAC ducts. Another benefit to drop tile ceiling systems is they are typically less expensive than drywall.

There is a “popcorn ceiling.” This means the facility probably was built between the 1950s and 1980s. These ceilings are not necessarily bad in and of themselves, though. At the height of its popularity this type of ceiling finish was cheaper and faster to install than painting, helped with acoustics, and added some fireproofing. Today, however, it can make a room look dated.

But even more worrisome is that some of this material was manufactured with asbestos. If the popcorn ceiling was installed before 1978, fms should call in a professional for testing; removal shouldn’t be attempted by in-house staff.

But how can this type of ceiling be changed out for a new one? Removing the finish is very difficult and time consuming. One solution is to install resilient isolation clips to the joists and attach hat tracks (See images at right). This allows fms to have a new layer of drywall installed 2″ to 3″ below the existing ceiling. An added benefit is this soundproofs the space from the floor above.

We have a room in which we experience an awful echo. Certain acoustic conditions negatively impact large gatherings, teleconferences, and the like due to undue noise volume and low intelligibility in the space. This is more often than not an issue encountered with sheetrock ceilings because of their high sound reflectivity, and it is even more common with the raised shape variety because there is more volume and surface area, causing excessive reverberation.

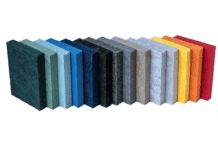

One solution is to add sound absorbing materials like acoustical panels or glue-on acoustic ceiling tiles. These panels can be installed flush to a flat surface or cathedral ceiling, placed within coffers, or suspended from curved surfaces. When suspended horizontally from the ceiling these panels are referred to as clouds, and when suspended vertically they are called baffles. Glue-on acoustic ceiling tiles are available in many patterns and colors, and can result in a finished look when installed over the entire ceiling surface.

If an fm is experiencing this issue with a drop tile ceiling, the existing ceiling tiles probably do not have a high enough NRC (Noise Reduction Coefficient) rating. NRC indicates how much sound a surface absorbs as opposed to reflects. Even drop tiles labeled as “acoustic” may have an unacceptably low NRC rating because suspended ceilings are sometimes generically referred to as acoustic, regardless of the acoustical qualities.

When shopping for drop tiles that will solve this existing noise issue, fms should be sure to check NRC ratings, and not settle for anything below an NRC .80 (this indicates the tile absorbs 80% of potentially reflected sound energy). Many acoustical ceiling tiles have ratings of NRC 1.00.

We can hear what’s going on in the room above or to the side through the ceiling. Here is where drop tile ceiling systems deliver on convenience once again. Replacing the existing ceiling tiles with sound blocking tiles, indicated by their STC (Sound Transmission Class) rating, will add mass to a ceiling system and reduce sound transmission. To be considered sound blocking, a ceiling tile should have a rating of at least STC 27 to 30. If getting rid of the existing tiles is a hard sell, drop tile ceiling barrier is a dense product sold in rolls or sheets the size of the existing tiles. This material can be laid down or rolled out on top of the existing drop tiles to increase the STC of the ceiling assembly. A lot of sound can also travel through the HVAC system in suspended ceiling plenums. Sound absorptive material such as duct lining can reduce sound travel, and plenum return silencers can be installed at vent openings to achieve the same result.

If working with a flat drywall ceiling, fms should make sure it is sealed. Penetrations for items like canned lighting will allow sound to pass through easily. Beyond this, damping compound like Green Glue sandwiched between an additional layer of drywall will help reduce noise from above. Loud structure borne sound and vibration like heavy footfall and other noises may require isolation hangers, creating what is known as a floating ceiling (as seen above).

Structure borne sound and vibration that transmits through drop tile assemblies can be mitigated by creating a resiliently suspended system with spring isolation hangers. This is usually only deemed necessary in critical environments like sound studios or testing facilities.

As part of a whole, ceilings can present problems for fms, in terms of appearance, acoustics, or both. Whether removing an existing ceiling, amending one that is in place, or building a new space, choosing the best suited material and having them installed correctly will provide an attractive, well performing space.

Sanford is communications specialist with Acoustical Solutions, a provider of acoustical products and services based in Richmond, VA.

![[VIDEO] Collect Asset Data at the Speed of Walking a Building](https://facilityexecutive.com/wp-content/uploads/2024/02/maxresdefault-324x160.jpg)

This article was really helpful. Thanks for the advice about using acoustic glue-on ceiling tiles if you have a room that echoes. We just moved into our new house and put the baby in a room with a vaulted ceiling, and it’s so loud in there. We can hardly walk in without waking up the baby, so maybe we should get some tiles make for ceilings to make it quieter.